AXI – Axial Illumination

Dino-Lite coaxial models have a built-in LED that shines onto a mirror which acts as a beam splitter. The mirror projects the light directly onto the sample, allowing the image that is formed to be returned directly back to the image sensor.

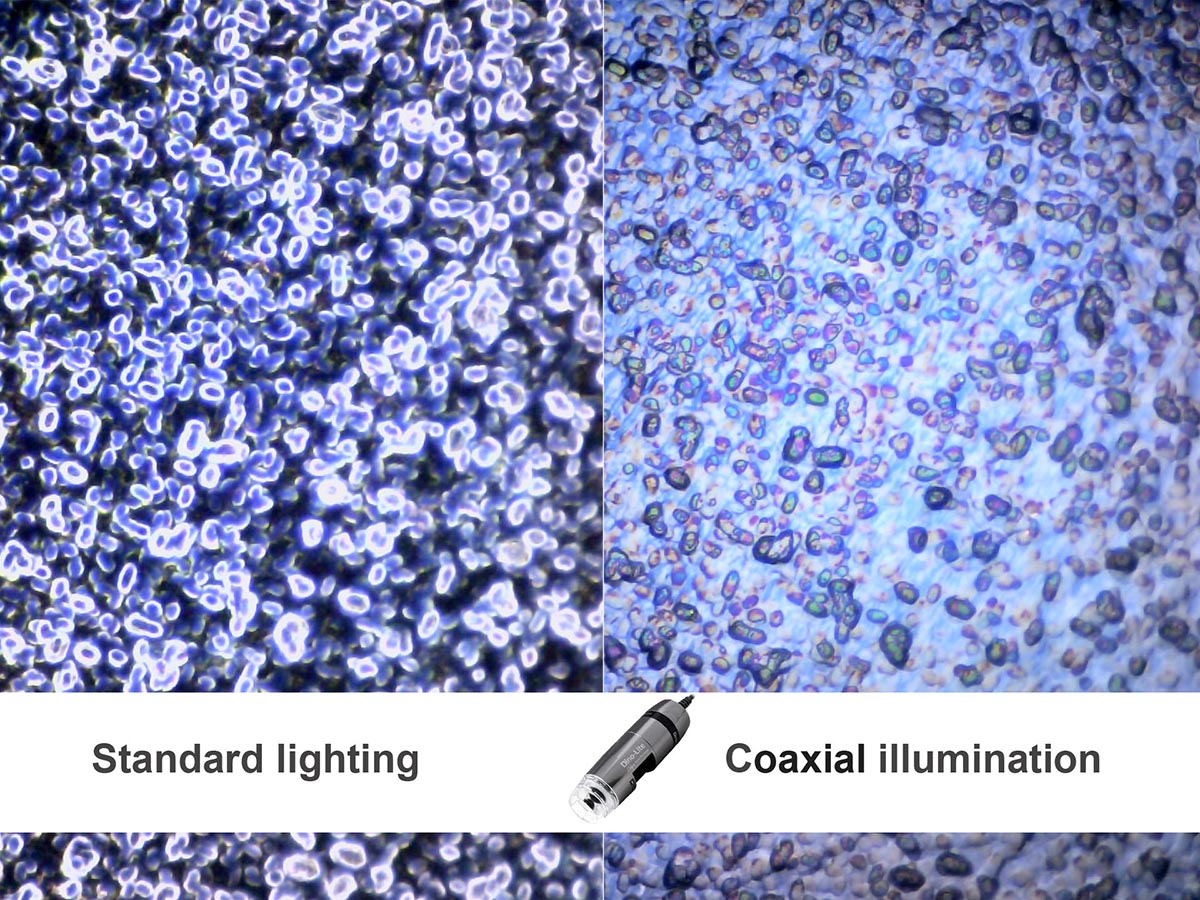

The most commonly used application for Coaxial illumination in the semiconductor industry is the quality control and inspection wafer plates. With standard brightfield illumination the structures and overlaying structures are not all visible, while with coaxial illumination these details will appear.

Application of AXI

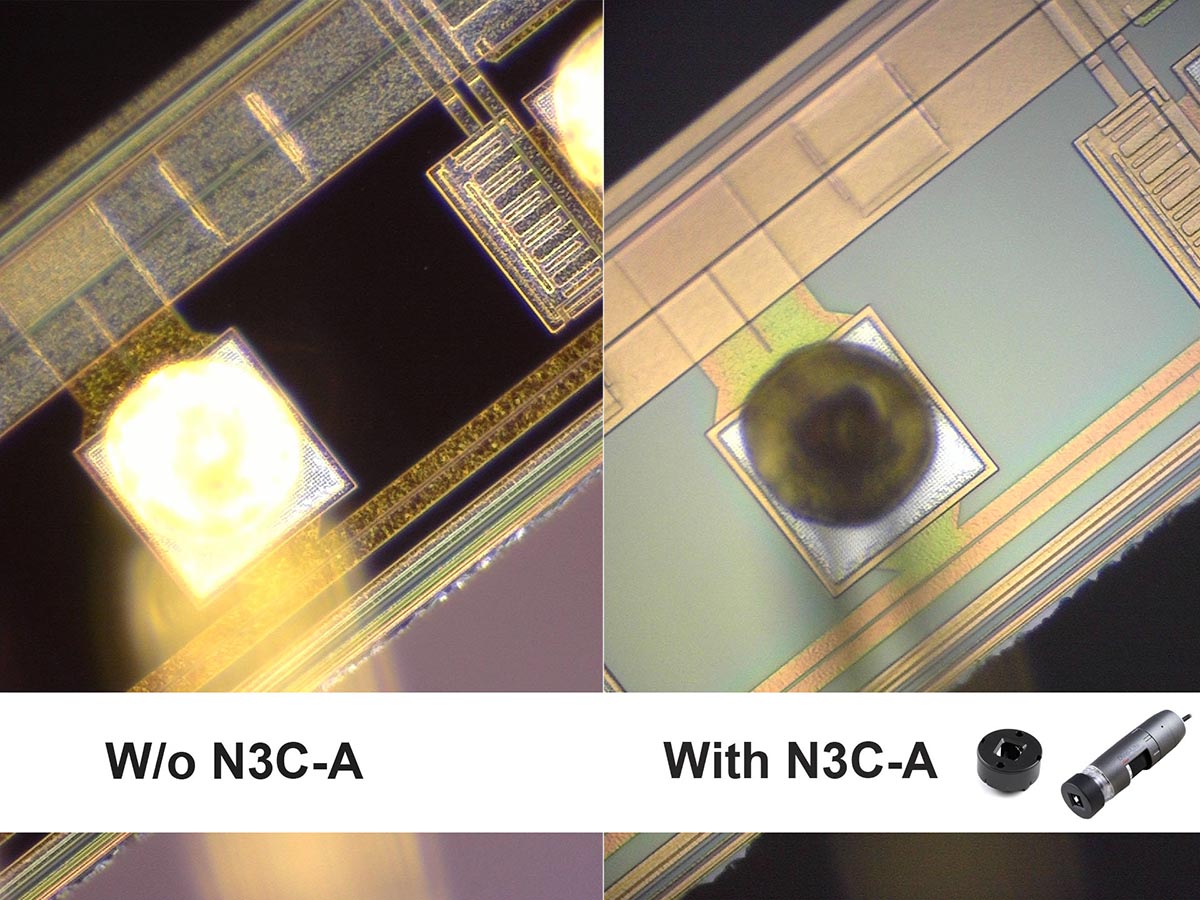

AXI can also be added to LWD models via the N3C-A

Dino-Lite Edge Long Working Distance (LWD) models can use the N3C-A to have the same effect as our AXI models. Standard models can use this attachment however, it does reduce the magnification range to below 50x or 225x

A wafer sample comparison image, notice the clarity provided to the image with the N3C-A attached.

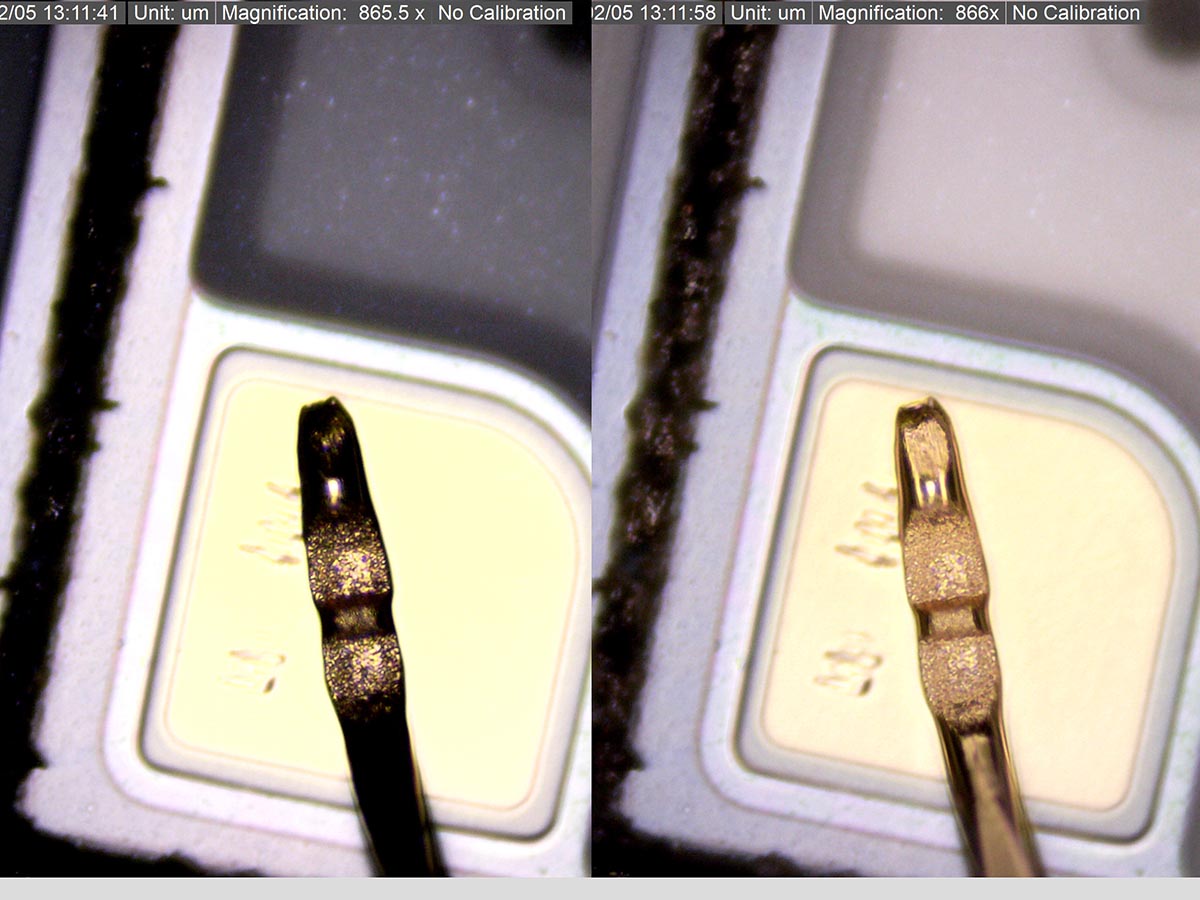

High magnification models have a great range of improvement

Due to it’s effectiveness at high magnification, newer Dino-Lite Edge Series High Magnification models have been outfitted with AXI to improve imaging results.

Sample with standard lighting (left) compared to the clarity with AXI enabled (right)

Reveal textures or imperfections on surfaces

AXI can help reveal details that could otherwise be easily missed. Improve the effectiveness of your inspection easily with an AXI model. We can even perform a demonstration on your sample subject, contact us for more information!

Surface sample with standard lighting (left) and AXI (right)

Recommanded Microscopes

-

Edge 3.0

Edge 3.0AM73515MT8A

5MP, USB 3 with FLC, AXI, AMR & High Mag$1,469.00 VIEW COMPARE -

Edge Series

Edge SeriesAM7515MT4A

5MP with FLC, AXI, AMR & High Mag$1,129.00 VIEW COMPARE -

EdgePLUS

EdgePLUSAM4517MT8A

1.3MP with eFLC, AXI, AMR & High Mag$1,095.00 VIEW COMPARE -

Edge Series

Edge SeriesAM7515MT2A

5MP with FLC, AXI & AMR$1,069.00 VIEW COMPARE